Chrome Plating Laboratory

TAF Certified Chrome Plating Lab

Cherng Min as a Taiwanes exterior car accessory supplier has already transformed from a price competitor to become more targeting on the electroplating technology developing and the quality of products. Their change does not only allowed them to sell in the U.S., but also in Europe.

In Cherng Min, we also self-design gauges in order to conduct testing in particular parts of our products. The gauges are regularly examined to ensure its precision. Because we are always obtaining certifications, our auto accessory is built to meet international standards in the U.S. and Europe.

Laboratory certification program ensurues laboratories are able to carry out accurate testing using particular methos which have been approved.

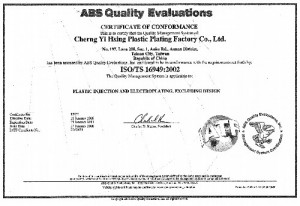

TAF, ISO 9001, ISO 17025 and TS 16949 Certified

TS 14949 is obtained by Cherng Min for its quality management system, especially for automotive-related products including wheel covers, headcaps, chrome mirror covers, door handle covers and tailgate handle covers.

ISO/IEC 17025 Recognition Laboratory - Test Method

- CASS Resist Test

- QTC Test Machine

- TCT Test Machine

- Thickness Test Machine

- Stone Chipping Test Machine

- Drop Tester

- Force Gage

- Ductility Test

- Active Site Test

- Thickness Test

- STEP Test

- CASS Test

- Peeling Test

- QTC Test

- Microporous Test

- Saw Grinding Test

- Stone Chipping Test

- Drop Test

- MacBeth Light Machine

- Metallurgical

- Thickness Test

- PS-8810:

- Cr: 0.25↑µm

- Ni: 21µm

- Cu: 15µm

- Bright Nickel: 8µm↑

- Semi-Nickel: 13µm↑

- STEP: Microporous-Brght 0-40mv Brght-Semi 110-200mv

- GMW14668:

- Cr: 0.25~0.5µm

- Ni: 20µm

- Cu: 20µm

- Total Thickness: 40µm↑

- STEP: Microporous-Brght 10-40mv Brght-Semi 100-200mv

- CASS Test

- ASTM B368

- Pure Water + NaCI 50g/ + lCuCl2 0.25 g/l

- Quantity of Fog:

- a. 1.0 to 2.0mL/(80cm2.h)

- b. pH: 3.1 to 3.3

- c. Specific Gravity: 1.030 to 1.040

- Air Pressure: 1.00& ± 0.01 Kgf/cm2

- Chamber Temperature: 49 ± 1°C

- Air Pressure Temperature: 63°C

- Thermal Cycle Test

Thermal Cycle Test & Quick Thermal Cycl

- PS-8810

- 82°C 1hr

- Room temperature 1hr or less 1hr

- -35°C 1hr

- Room temperature 1hr or less 1hr

- GMW14668

- -40°C ± 3°C* 1 hr

- 90°C + 3°C*1hr

- Chipping Stone Test

GMW14668

- Microporous Test

Activated Site / Microporous: 10000 pores/cm2 above